Manufacturing

How Finesse components are made

Across our range of small parts, every material and method is chosen with intent—built to strike the sweet spot between strength, precision, and quality.

Used for all PA12 parts

Multi Jet Fusion (MJF) 3D Printing

Multi Jet Fusion (MJF) is a high-performance 3D printing process that builds strong, functional parts from fine PA12 nylon powder - our go-to for all Finesse nylon components.

It works like this: A layer of powder is spread, fusing agents are precisely applied, and heat locks it all in - layer by layer - until the part is done. No support structures, no wasted motion. Once cooled, the unused powder is brushed off, and up to 80% gets recycled for future prints.

MJF gives us freedom to design without compromise. It's fast, accurate, and built for real-world performance - just like the parts it creates.

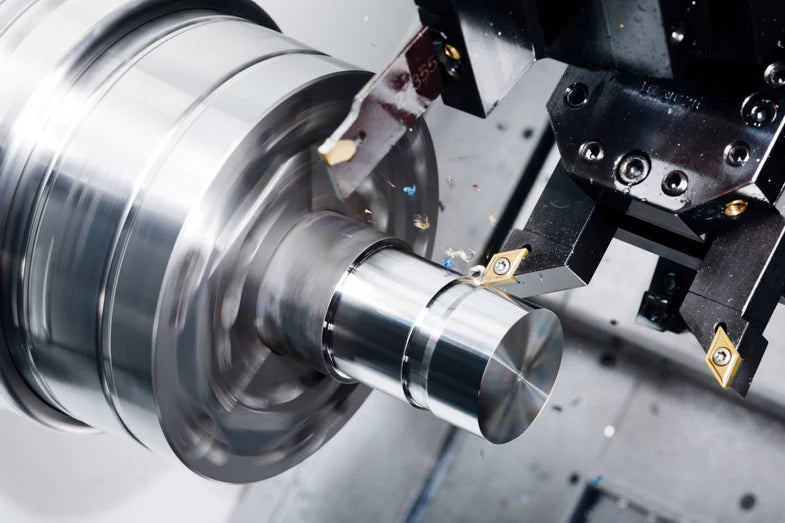

Used for all custom bolts

CNC machning

CNC Turning is all about precision. Metal rods spin at speed while cutting tools shape them down to the exact spec - perfect for round parts like bolts, axles, and spacers.

Each piece starts as solid bar stock, then gets machined with tight tolerances and a clean finish. The result? Dialed parts that look as good as they perform